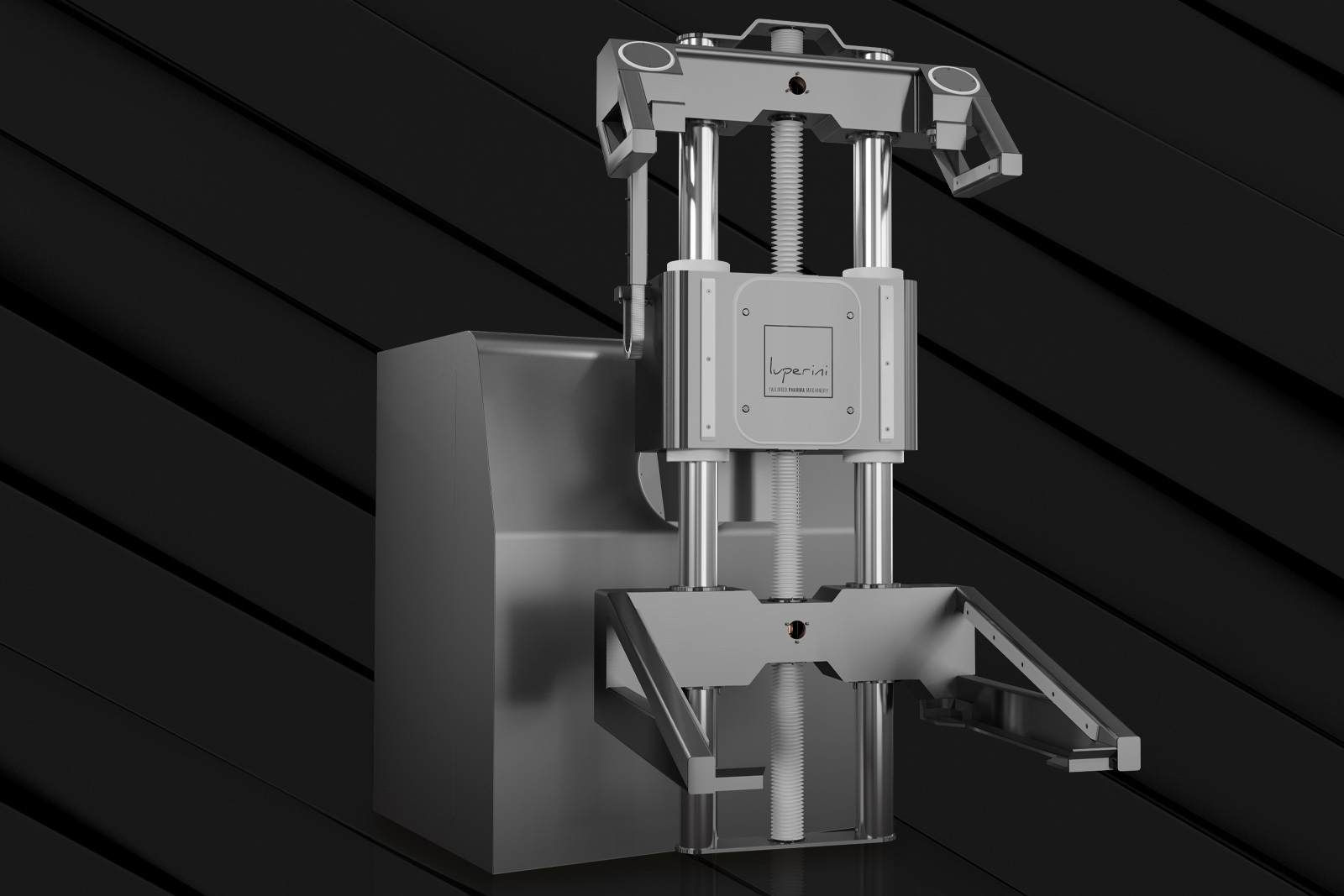

Mixing with IBCs is the most efficient way to mix powders and granules in the pharmaceutical industry. The I-TUMBLER is an IBC mixer designed to mix and homogenise powders and granules. The particular design of the cage, according to a system of combined inclinations, creates an asymmetrical movement of the product in the IBC allowing high mixing efficiency even with “difficult” products.

Enhanced security features

- Wireless technology for continuous signal transmission

- BIN clamping system with Force Cells to ensure efficient and continuous clamping of the container to the rotating structure

(BIN holder cage)

Safe and robust, variable speed with acceleration and deceleration ramps. If the machine’s production capacity needs to be increased after purchase, an upgrade can be carried out to increase the size of the loadable Bins. The various versions of the I-TUMBLER have some standardised structural parts capable of withstanding the loads of the larger Bins. This design allows the machine to be transformed for increased production capacity using a conversion kit, which is easy to install and very cost-effective. I-TUMBLER is the only machine in the world capable of mixing containers from 600 to 2200 litres for standard productions, from 1200 to 2800 litres for large-scale productions.

Photo gallery

Related products

Optional

- The different types of I-TUMBLER are conceived and designed to meet any productivity requirement, from small laboratory batches to high output industrial production.

- Possibility of installing NIR probes to monitor the mixing process.

- The I-Tumbler can be can be wall-mounted (“through-wall”) to reduce space requirements and optimise space in the process area.

Benefits

- High productivity.

- Loading and unloading of containers is much easier and faster thanks to the positioning of the lower platform on the ground.

- Efficient product mixing due to the special position of the IBC.

- Wall-mounted installation possible.

- Very simple operator interface.

- Saving and management of mixing recipes.

- Validation according to GAMP standards.

- Conformity to 21 CFR Part 11.

- Platforms, central body and structure are made of AISI 304 stainless steel with a satin finish and any excess removed by a manual finishing process.