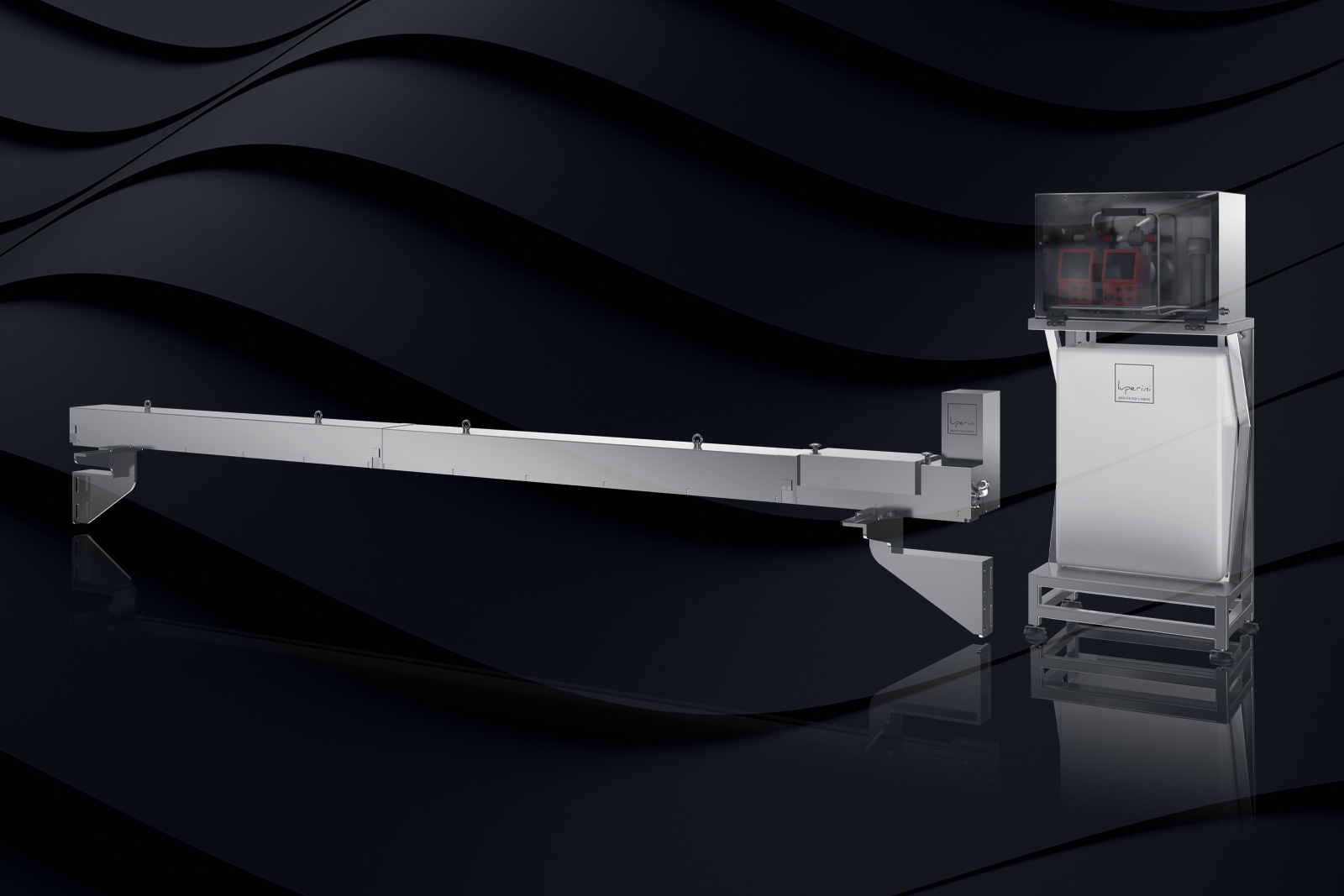

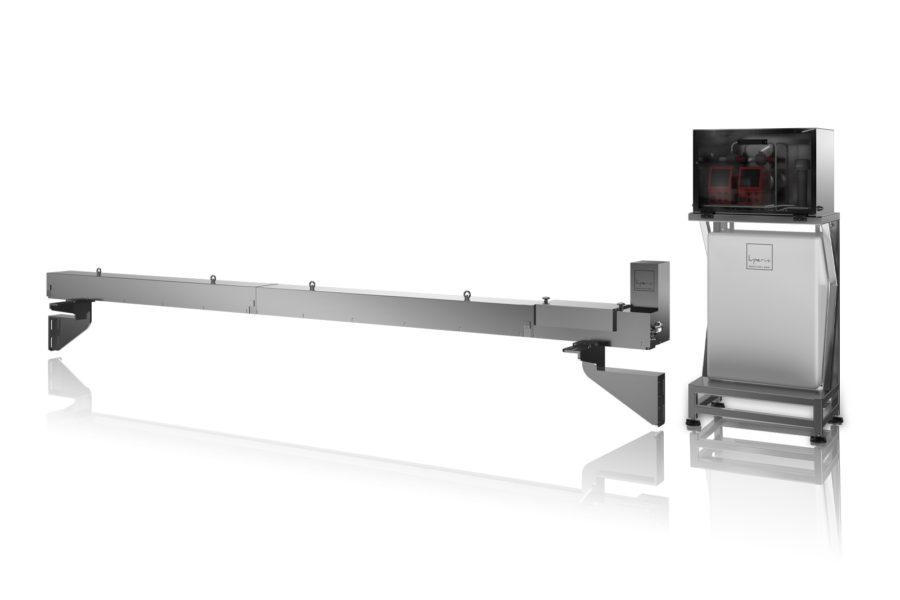

The SpraySled is designed for treating cylinders and drying sheets using Acquaflex Wiretec technology. The system consists of a structure containing pumps and an electrical panel, and a linear unit with a mobile carriage, upon which the nozzle is positioned. The SpraySled is designed to operate in “difficult” environments, wet areas, and high temperature areas. The management software allows to monitor all the SpraySled’s parameters. The paper machine’s status (paper presence, speed, paper breakage), the pump’s flow rate, and the position and speed of the nozzle can be viewed and modified from the operator’s panel (touch screen).

The Wiretec technology by Acquaflex avoids the formation of organic deposits on the cylinders and drying sheets by preventing the particles with adhesive properties present in the paper (“stickies” and/or pitches) from adhering to their surface; it also helps improve the lubrication of the scrapers, thus reducing the friction coefficient between the scrapers themselves and the drying cylinders.

The Wiretec technology involves the application of an undiluted product upon the surface to be protected (cylinder or cover) using a single nozzle, which moves cross-wise in relation to the paper machine; this creates a passivation film, which is ultra-thin (just a few nanometers), but is capable of preventing the adhesion of adhesive and/or thermoplastic substances. The product is usually applied to the first cylinder and/or the first drying sheet, and then spreads to the subsequent cylinders and/or sheets.

The experience that Acquaflex has gained with dozens of different applications allows for the formulation and selection of the optimal product based on the type of surface to be treated, its temperature, and the type of deposit present within the production cycle.

Photo gallery

Advantages

- Elimination and prevention of deposits on cylinders and drying sheets

- Easier removal of the sheet

- Decreased stripping and dusting

- Better moisture profile

- Better sheet smoothing

- Fewer breakages and stops for cleaning

- Lower maintenance costs

- Maximum heat exchange efficiency (decreased steam consumption)

- Possibility of extracting the SpraySled with the machine in motion

- Increased production

Material specifications

- Sled support structure AISI 304 stainless steel

- External casing AISI 316L Stainless steel

- Aluminium sled

- Pump frame and electrical panel AISI 304 stainless steel