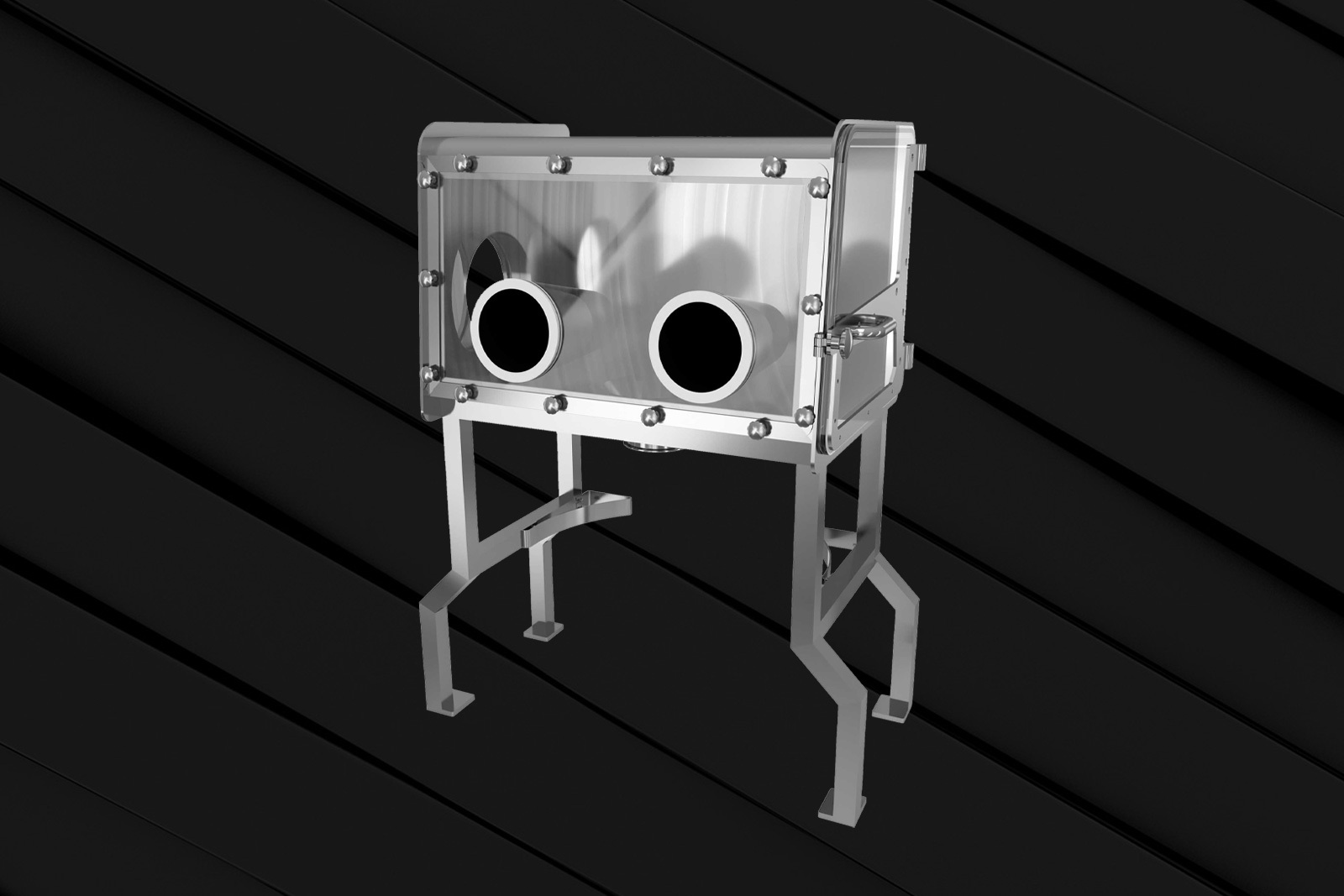

The I-Isolator is a booth for “dispensing” operations used for the preparation and weighing of raw materials. It is equipped with a front door in glass or clear polycarbonate, in which the housings for the product handling gloves are encased. The fixed or openable side doors can be made of AISI 316L stainless steel, glass, or clear polycarbonate. The doors have tubular or inflatable silicone seals.

The I-Isolator has a conical discharge hopper at the bottom, to which a manual or automatic valve is connected.

The I-Isolator is available in fixed and stand alone versions.

The I-Isolator is a modular booth that can be equipped with accessories and control instruments for the management of any “dispensing” activity.

Various components and accessories are available in our catalogue for use in the pharmaceutical, fine chemical and food industries.

We are able to customise our products and design new ones based on specific requirements.

Photo gallery

Advantages

- Modular booth.

- Fixed or Stand Alone version.

- Possibility of providing custom solutions for “dispensing” activities.

- Ergonomic and functional.

- Ease of disassembly and cleaning.

- Discharge connection via flexible silicone hoses.

- Washable in line with CIP or WIP systems.

- Durable and reliable.

Material specifications

PARTS IN CONTACT with the product made of certified AISI 316L stainless steel:

- Glossy internal finish, Ra 0.5 micrometers.

- Internal welds smoothed and polished to a Ra of 0.5 micrometers.

NON-CONTACT PARTS:

- Welds smoothed and ground to a Scotch-Brite finish.

- Parts not in contact with the product made of AISI 304 stainless steel.