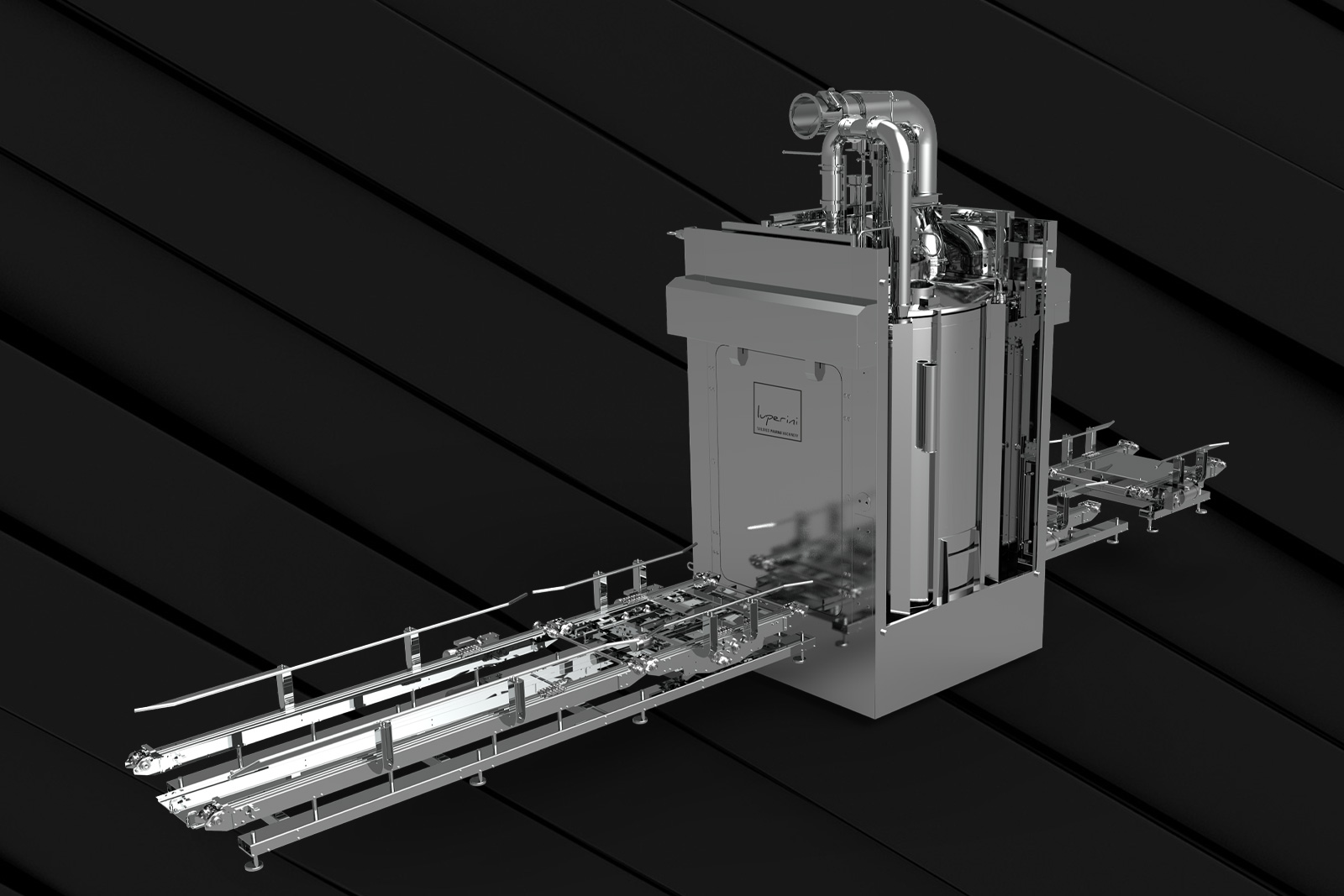

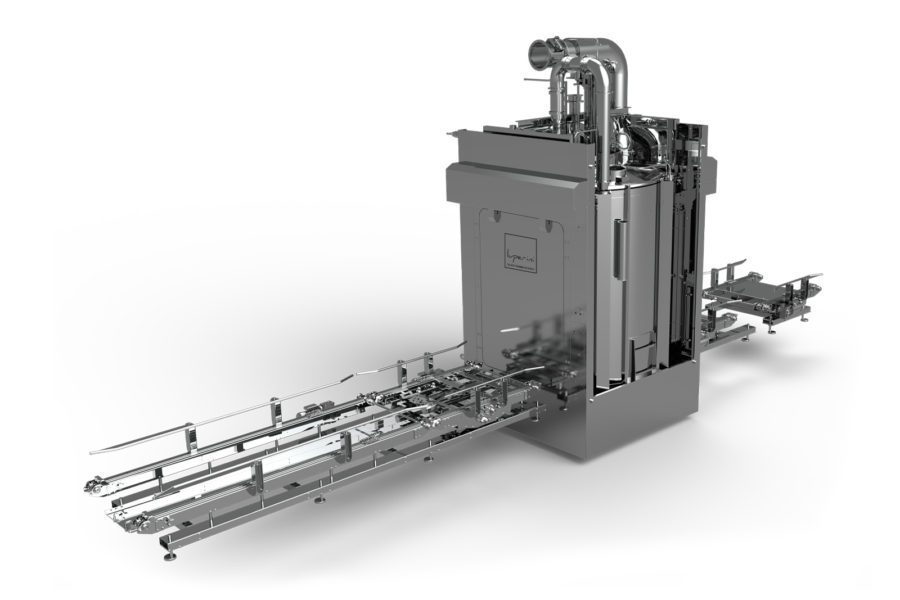

The I-Washing system is designed for washing and drying Luperini I-Pharma Bin containers, other types of IBCs, and other components commonly used in the pharmaceutical industry that need to be washed and dried thoroughly and frequently.

Manual, semi-automatic and fully automatic washing systems are available, depending on the level of automation required.

Functional description

- Pre-washing with decalcified tap water.

- Washing with tap water and detergents (if required).

- Rinsing with decalcified tap water.

- Rinsing with purified water.

- Purging of the washing lines with compressed air.

- Blowing of the Bin with compressed air

- Drying of the Bin with hot air at a high flow rate, with a blade introduction system for better drying every part of the bin.

The I-Washing system can be designed with a single, double or triple booth, with one or more doors arranged in line or at 90°. This configuration enhances the washing and drying performance. Possibility of through-wall installation for the separation of dirty/clean areas.

Photo gallery

Related products

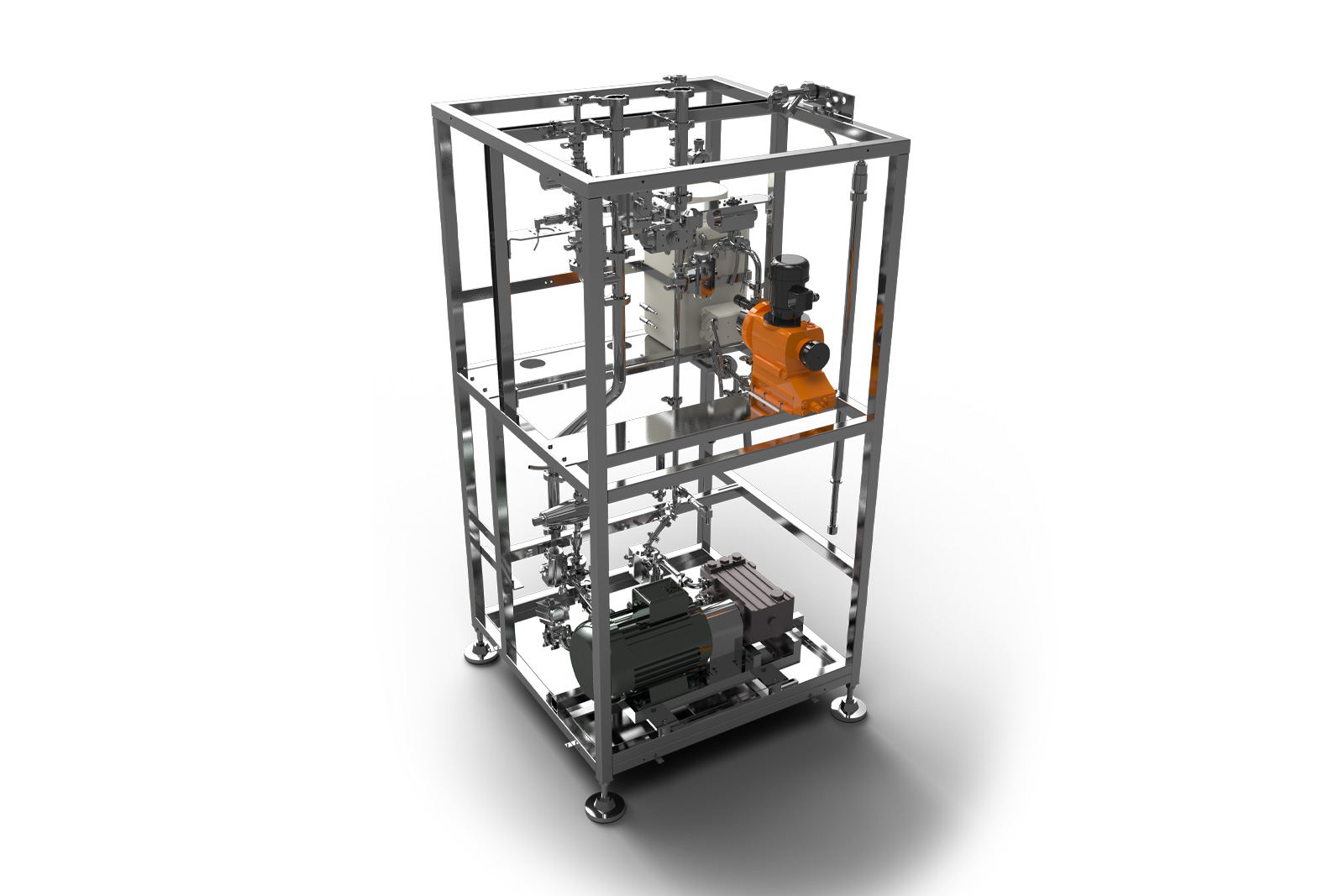

Mobile pump unit for easy installation and transport in technical areas.

Pump unit required for pressurising the wash water at medium or high pressure. The skid consists of connections, valves and manifolds required for connection to the utilities. The skid is supplied complete with tanks for detergents, which are dosed manually or automatically in the washing chamber.

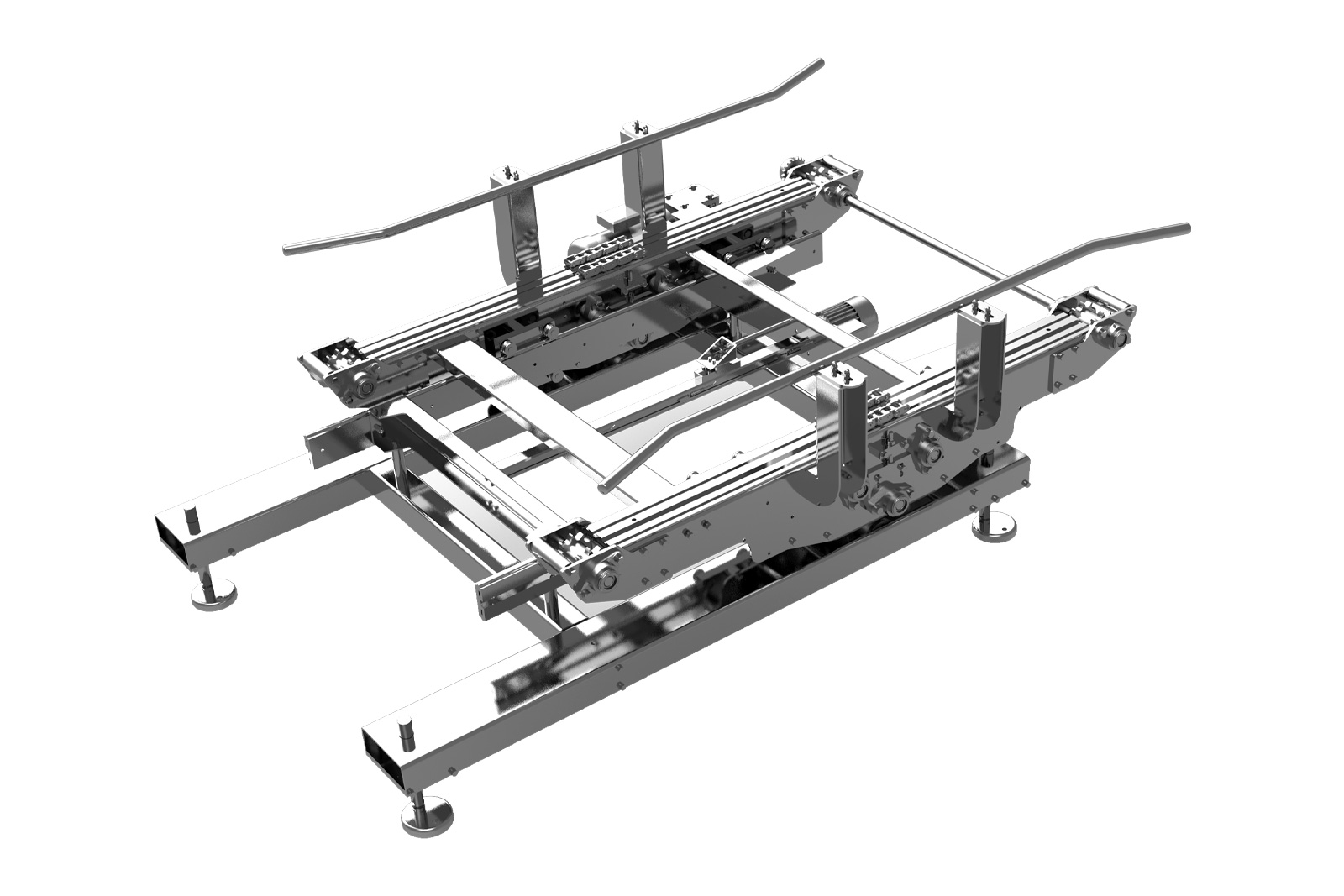

Customised racks for drums, lids, hoppers and various accessories.

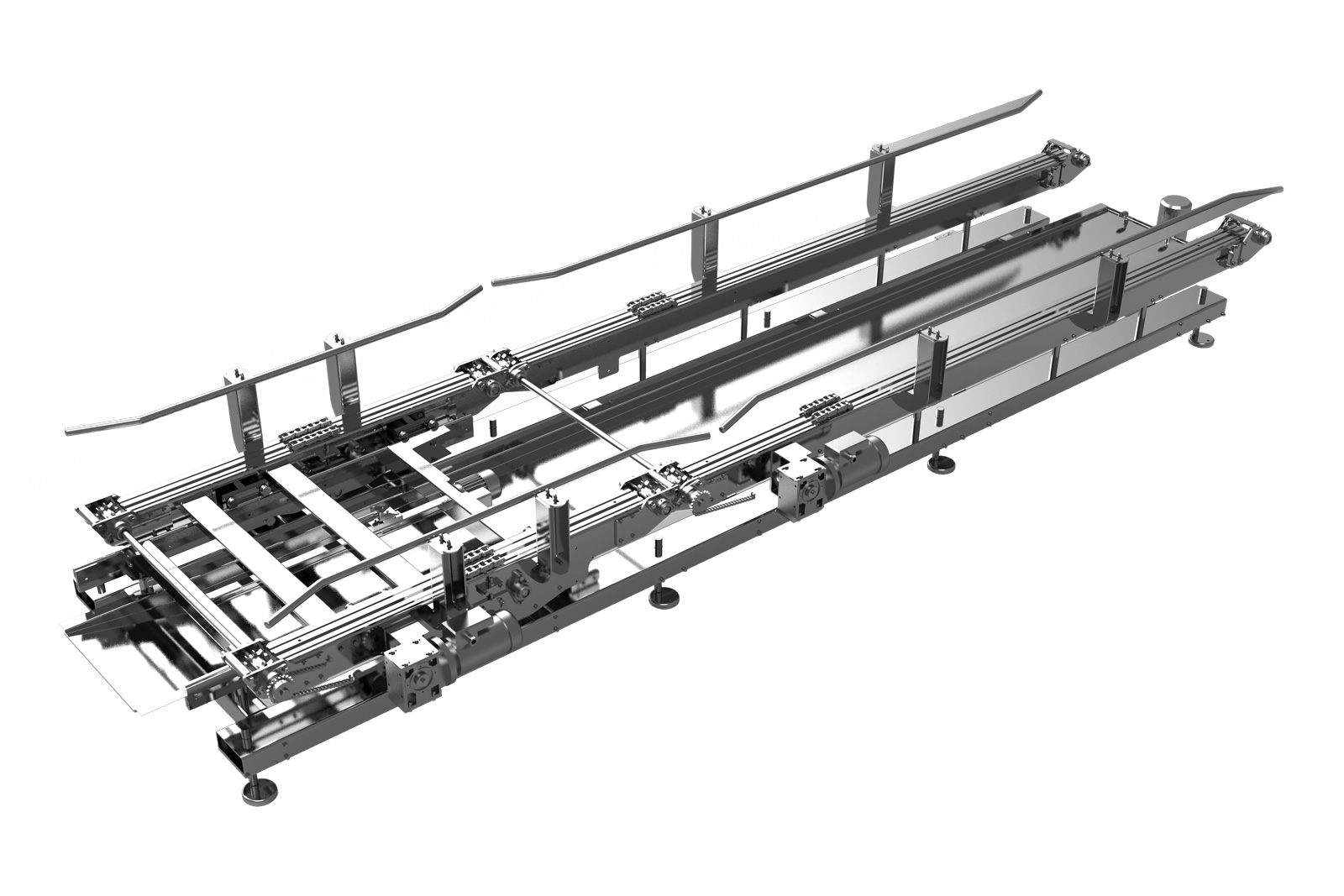

Single or multi bin conveyor system. Allows one or more bins to be stored while waiting for washing. Modular and automatic system.

Single or multi bin conveyor system. Allows one or more bins to be stored while waiting for washing. Modular and automatic system.