The I-Pharma Bin is designed and built according to the GMP standards for the containment of powders, granules and liquids.

The I-Pharma Bin is available in various versions: square, rectangular, fixed, or wheeled for easy handling. The I-Pharma Bin can be equipped with accessories for the containment and handling of liquids upon request.

Standard sizes from 3 to 2200 L, with 2500 to 3000 L versions available upon request. Designed with maximum attention to detail, it facilitates product unloading and prevents water from pooling during washing.

- Standard design powder containers with a square layout. Custom containers available upon request. Transportable with manual or electric pallet trucks, forklifts, AGVs, etc.

- Possibility of installing high containment valves for unloading and filling operations at risk of contamination.

- Possibility of installing valves suitable for handling liquids.

- Possibility of applying certified coatings to improve the product’s movement.

- Manual and automatic butterfly valves for emptying powders and liquids.

- Accessories available; label holders, barcode and QR code readers, numbering, tare weight, wheels, and other accessories available upon request.

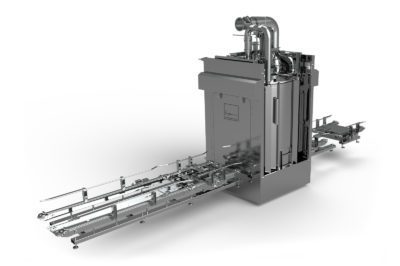

Photo gallery

Related products

Advantages

- Surfaces meticulously designed to ensure better product movement and to prevent water from pooling during washing.

- Durable design that allows the I-Pharma Bin to be mixed using the I-Tumbler.

- Numerous customisation possibilities.

- Food-grade silicone gaskets.

- DN 400 lid in AISI 316L stainless steel, with handle, clamp closure, and safety pin to prevent accidental opening.

- Guides for the use of electric or manual pallet trucks and forklifts.

- Self-centring containment buckets for vertical storage in the warehouse.

- Various valve models available for installation on the discharge.

Material specifications

PARTS IN CONTACT with the product made of certified AISI 316L stainless steel:

- Lossy internal finish, Ra 0.5 micrometers.

- Internal welds smoothed and polished to a Ra of 0.5 micrometers.

NON-CONTACT PARTS:

- Body and support structure with satin finish.

- Welds smoothed and ground to a Scotch-Brite finish.

- Parts not in contact with the product made of AISI 304 stainless steel.