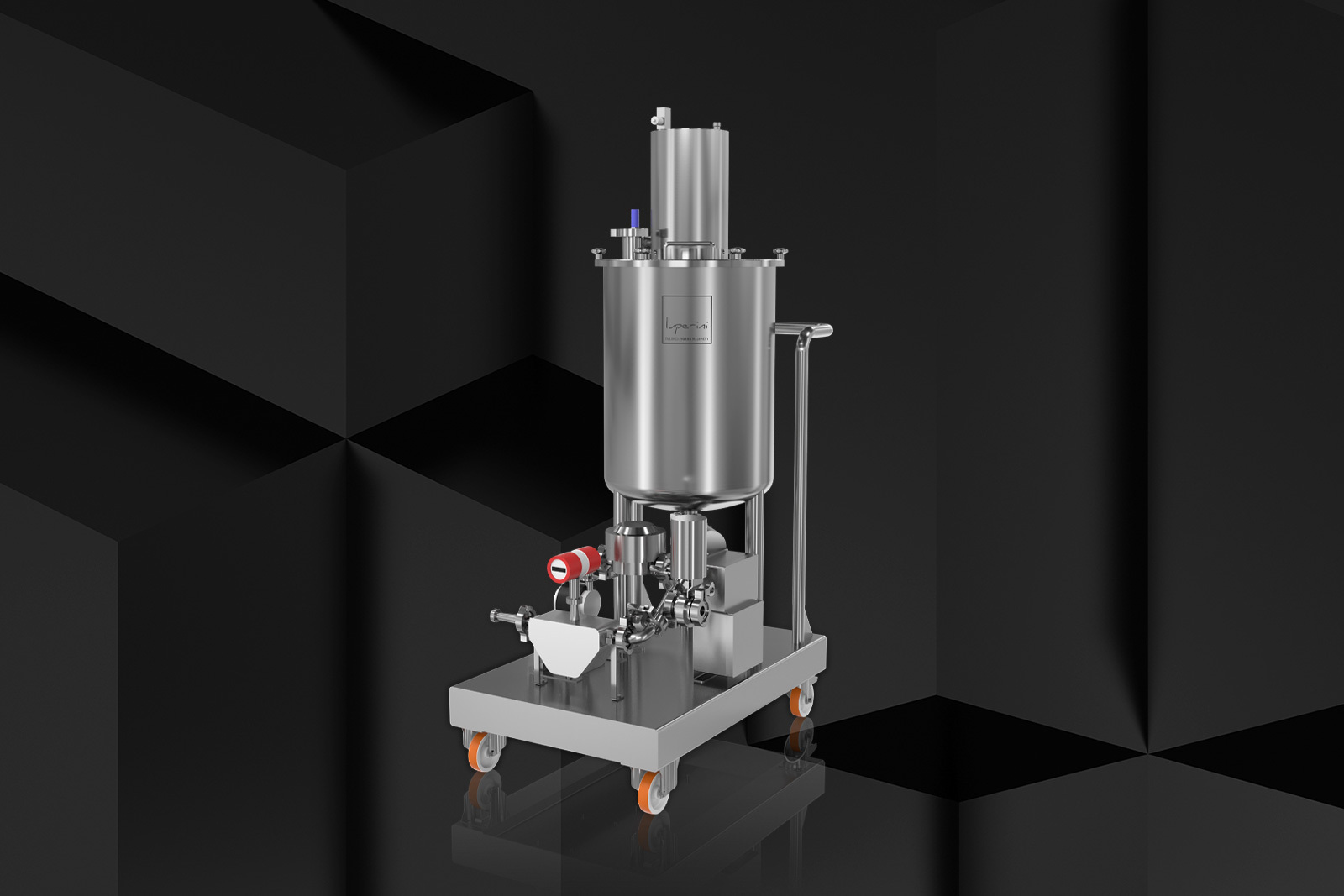

The I-Binding Solution is a mobile unit for binder solutions and generic liquids. The frame is mounted on wheels and comes equipped with a customisable AISI 316L stainless steel preparation vessel, with or without heating. An electric or pneumatic stirrer for liquids can be installed on the lid of the preparation vessel if the unit is intended to be used in classified environments. The system consists of rigid tri-clamp pipes, a pneumatic diaphragm pump, and an optional in-line flow meter.

In the version integrated with the I-POT, the I-Binding Solution is managed directly from the granulator’s control panel, and can be connected via a dedicated electrical plug. Possibility of in line washing with CIP or WIP systems.

The stand alone version of the I-Binding Solution has an electrical panel and a control panel mounted on its frame. It is powered by an electrical plug, and can be used to manage multiple binder solutions or generic liquids.

Both versions are Atex certified for use in classified environments.

Various components and accessories are available in our catalogue for use in the pharmaceutical, fine chemical and food industries.

We are able to customise our products and design new ones based on specific requirements.

Photo gallery

Related products

Advantages

- Unit mounted on an easy-to-transport trolley.

- I-POT integrated version or Stand Alone version.

- Possibility of custom solutions.

- Washable in line with CIP or WIP systems.

Material specifications

PARTS IN CONTACT with the product made of certified AISI 316L stainless steel:

- Glossy internal finish, Ra 0.5 micrometers.

- Internal welds smoothed and polished to a Ra of 0.5 micrometers.

NON-CONTACT PARTS:

- Welds smoothed and ground to a Scotch-Brite finish.

- Parts not in contact with the product made of AISI 304 stainless steel.