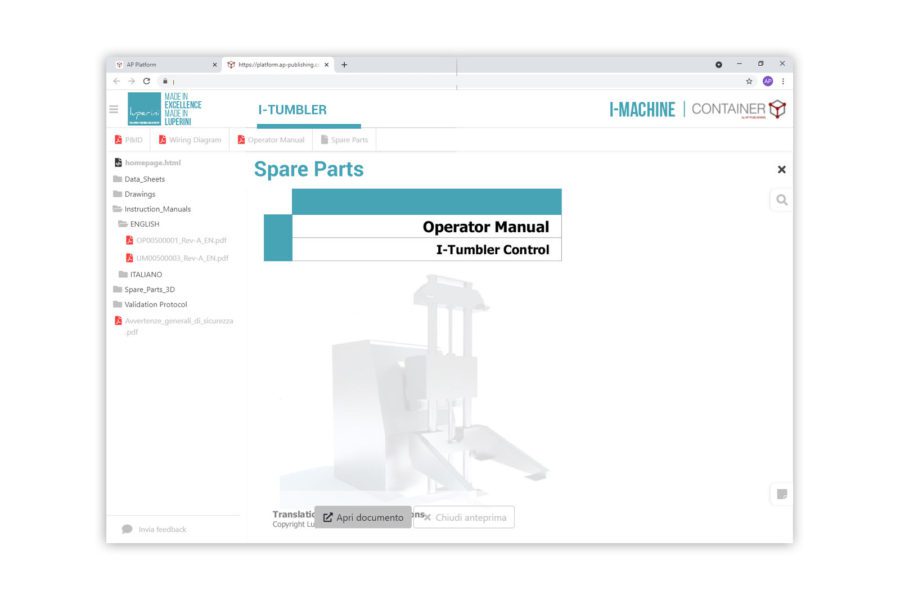

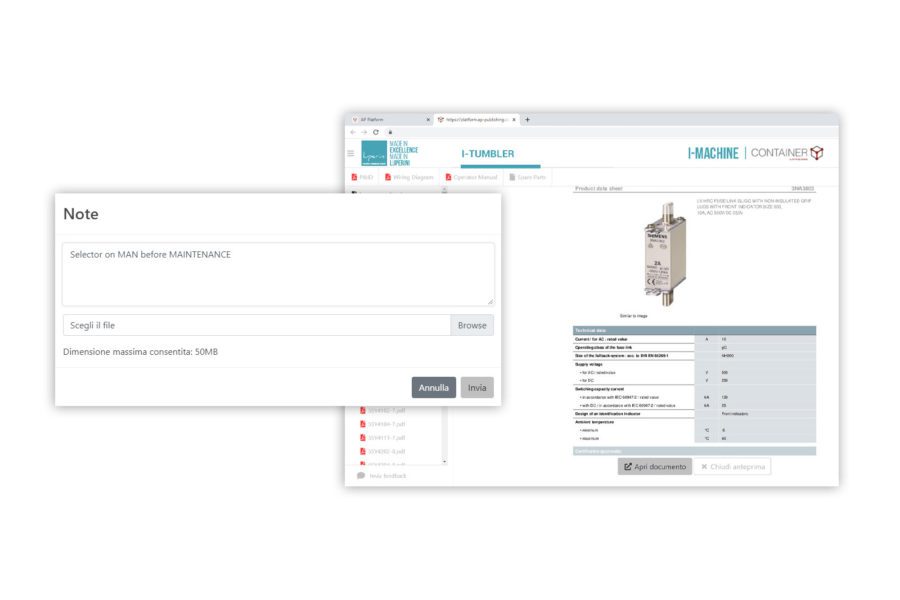

The Luperini company is highly attentive to customer care. In addition to respecting the international standards for the preparation of machine documentation (CE), Luperini also provides its customers with a software application that allows them to view and analyse all the machine’s technical documentation. The technical annexes, drawings, instruction manuals, spare parts, quality documentation, and validation protocols can all be found within a single application, in electronic format. Integrated functions, content organisation, search by description or code, and the possibility of inserting notes and comments: these are just some of the functions that Luperini offers to its customers.

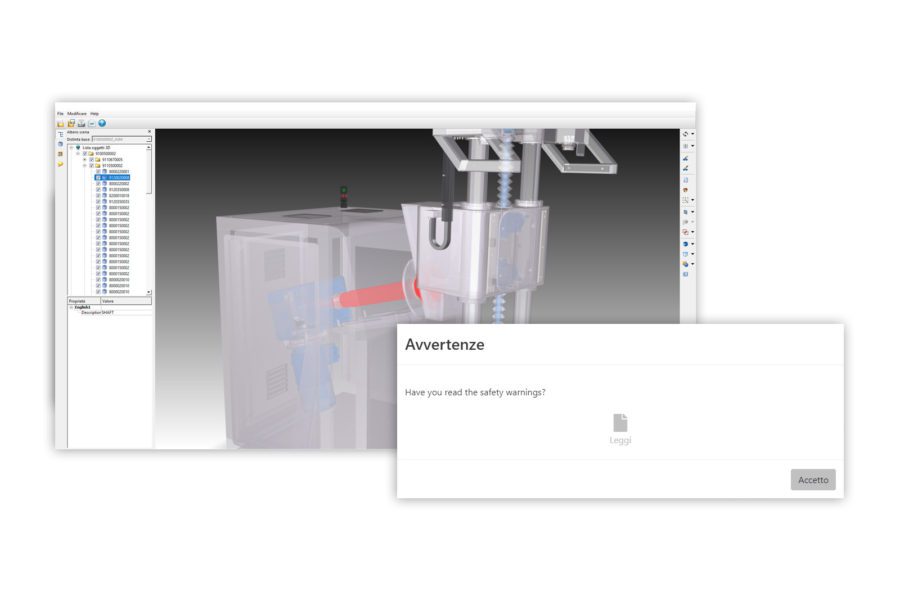

With I-MACHINE, your machine goes three dimensional

Luperini doesn’t just offer its customers a spare parts catalogue, but provides them with a customisable and interactive 3D model of the machine itself.

The user can search for the codes by selecting the part in question directly from the 3D model, prepare maintenance procedures, train their maintenance staff by analysing the machine’s individual units, and exploit the potential of collaboration tools by adding notes and comments.

The possibility of viewing the 3D model of the machine allows the design to be understood more quickly, even by the less experienced users. By clicking on the specific part, the user can immediately view the code, name, raw material used for production and quantity. Parts of the machine can be easily hidden, and specific parts can be isolated, enlarged, and analysed in detail.

Photo gallery

- The tools that Luperini places at its customers disposal allow them to perform detailed analyses of units or individual components, viewing them in both cross-section and transparent-section, which is useful for studying their disassembly and for training maintenance personnel.

- The ability to take advantage of collaboration tools allows for the insertion of hyperlinks within notes and comments: links to web pages or documents on the company’s servers, such as isolation, safety, cleaning, and decontamination procedures (INSTRUMENT COLLABORATION).

- The ability to print the selected view allows for personalised company procedures to be created with no need to disassemble any parts (SCREEN PRINTING).

ACCESSORIES

Animated maintenance procedures with comments

Thanks to the possibility of using the machine’s 3D files, Luperini offers its customers a “step by step” guide system for the maintenance and replacement of the machine’s parts. The videos will be produced on request, and will provide the maintenance worker with detailed information about the procedure for implementing the necessary safety measures on the machine prior to maintenance, the PPE and the tools to be used for the activity in question, the time required for the maintenance operation, and the checks needed to verify that the part subject to maintenance has been assembled correctly.

TABLET VERSION

The I-MACHINE software can be installed on a tablet on board the machine itself. This configuration allows this amazing tool to be utilised directly while the maintenance is being performed on the machine. The operator in charge of maintenance will be able to monitor the procedure on screen, pausing and restarting playback as needed to make sure that all operations have been carried out correctly.

I-MACHINE TRAINING

Luperini offers a training package on the use of the I-MACHINE software for procurement, maintenance, and safety personnel.

The main purpose of this package is to train personnel who carry out specific daily activities, to render the work of multiple departments linear and collaborative, and to simplify the downstream manual activities, in order to achieve better efficiency and productivity.